Anti-Foam Control Solutions-- Trusted Foam Control for Chemical Handling

Anti-Foam Control Solutions-- Trusted Foam Control for Chemical Handling

Blog Article

Finest Practices for Choosing the Right Anti-Foam Control Service for Your Needs

Selecting an effective anti-foam control service demands a thorough evaluation of your one-of-a-kind functional requirements. Secret factors to consider consist of the specific residential properties of your process, such as ph, chemical, and temperature interactions, all of which considerably affect the efficiency of defoaming representatives. Making sure compatibility with the tool and adhering to governing requirements are necessary for successful execution. As we explore these vital aspects, it comes to be apparent that the right options can lead to not only immediate advantages however also lasting functional renovations that warrant further examination.

Understand Your Foam Issue

Regularly, organizations encounter foam-related problems that can impede functional effectiveness and product high quality. Foam development can happen throughout different processes, including mixing, fermenting, and transport, and it usually brings about devices inadequacies, manufacturing downtime, and boosted operational prices. Understanding the underlying sources of foam generation is crucial for dealing with the issue effectively.

Foam can emerge from several variables, such as the nature of the products included, anxiety levels, temperature variants, and chain reactions. Certain surfactants can intensify foaming, while high shear mixing can present air, leading to undesirable foam accumulation. Furthermore, environmental problems and the specific characteristics of the liquid systems in operation can substantially influence foam habits.

Identifying the kind of foam-- whether it is unsteady or steady-- is also essential. Steady foam often tends to persist longer and is much more challenging to handle, while unstable foam may dissipate much more easily. Anti-Foam Control Solutions. By examining these variables, companies can obtain insights into their foam problems, allowing them to create targeted strategies to reduce foam development and boost total procedure performance. This foundational understanding is important for picking an ideal anti-foam control solution tailored to specific functional demands.

Assess Anti-Foam Options

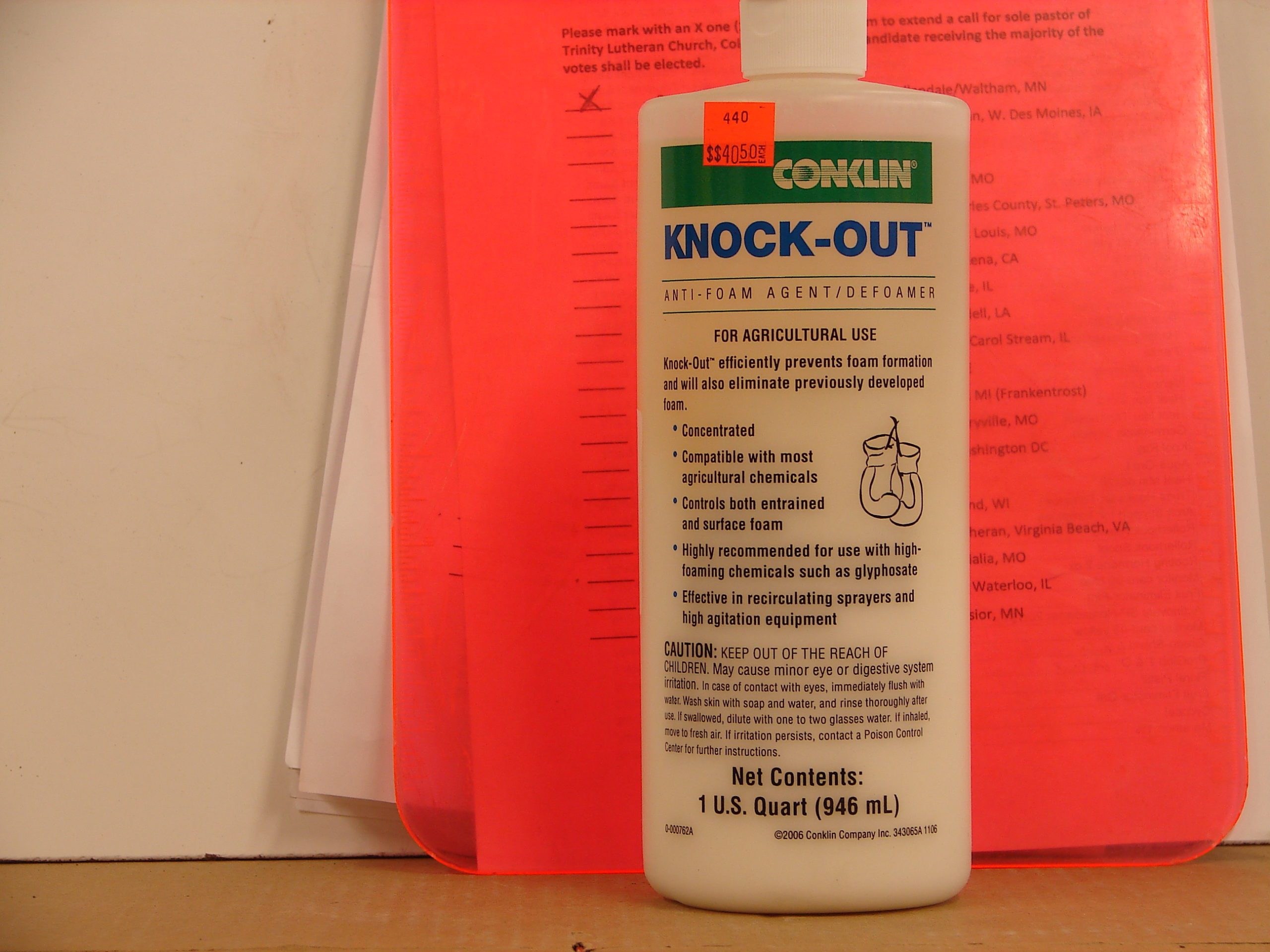

When considering anti-foam alternatives, it is necessary to thoroughly assess the different formulations available on the marketplace to find the most appropriate service for your certain foam-related difficulties. Anti-foam agents can be found in diverse kinds, consisting of silicone-based, non-silicone, and all-natural solutions, each offering distinct residential properties and efficiency characteristics.

Begin by analyzing the specific application requirements, such as temperature level thresholds, pH degrees, and the sort of foam being created. For example, silicone-based representatives are recognized for their performance in high-temperature environments, while non-silicone options might be more effective in food handling applications as a result of governing considerations.

It is likewise important to take into consideration the rate of application and the preferred longevity of the foam control. Some formulas might give instant defoaming action, while others provide long term stability. Carrying out small tests can provide insights right into the effectiveness of each alternative in real-world conditions.

Think About Application Compatibility

In the realm of anti-foam remedies, making sure application compatibility is paramount for achieving optimum efficiency. The effectiveness of an anti-foam representative greatly relies on its ability to operate sympathetically within the specific specifications of your application, consisting of temperature level, pH, and the presence of various other chemicals. Different formulas may carry out variably throughout diverse conditions, hence thorough testing is important.

Begin by identifying the attributes of your process, such as thickness and the nature of the medium in which the anti-foam will be employed. As an example, some anti-foam representatives may work well in aqueous solutions but fail in natural solvents. Furthermore, take into consideration the potential communications with existing active ingredients and products to stay clear of unfavorable results.

It is likewise important to review the approach of application. Whether the anti-foam is presented constantly or batch-wise can influence pop over to this site its efficacy and long life in the system. Make certain that the selected product is not just compatible with the operational parameters yet also aligns with any kind of regulatory needs relevant to your sector.

Assess Environmental Influence

Just how does the environmental effect of an anti-foam control remedy affect your overall selection procedure? The ecological footprint of your chosen anti-foam representative is vital, as it reflects your dedication to sustainability and regulatory conformity. Selecting a product with very little ecological consequences can improve your company photo and foster client trust fund.

When examining ecological impact, take into consideration the biodegradability of the anti-foam solution. Solutions with high poisoning can present significant risks to neighborhood communities, potentially resulting in governing penalties and environmental degradation.

Another critical factor is the presence of dangerous compounds. Anti-foams consisting of dangerous chemicals might demand special handling and disposal procedures, making complex and raising functional prices conformity with environmental regulations. Therefore, picking eco-friendly choices can alleviate these threats.

Monitor and Maximize Performance

To optimize the performance of your anti-foam control service, it is vital to frequently keep track of and optimize its performance. Continuous assessment permits the recognition of any kind of inconsistencies in foam levels and the succeeding performance of the anti-foam representative.

Carry out a click for more methodical technique to keep track of essential efficiency indications (KPIs), such as foam quantity, security, and the feedback time of the anti-foam representative. Use logical tools and techniques, such as aesthetic examinations, foam elevation measurements, and specialized sensors, to collect precise data.

In addition, maintain open communication with distributors for technical support and insights on the most recent advancements in anti-foam technology. This positive strategy not only help in accomplishing optimum performance yet likewise lessens operational disruptions and improves overall process effectiveness. Regularly revisiting and improving your anti-foam method ensures that you are properly managing foam-related difficulties, inevitably bring about improved efficiency and cost savings.

Verdict

In verdict, choosing the suitable anti-foam control option requires a detailed evaluation of details application requirements, including temperature level, pH levels, and chemical compatibility. Strenuous testing for immediate and prolonged defoaming efficiency is vital, as is factor to consider of environmental effects and regulatory compliance. By focusing on eco-friendly alternatives and continually monitoring performance, functional performance can be improved while properly mitigating foam-related obstacles. Complying with these finest methods will promote informed decision-making in anti-foam control remedies.

Choosing an efficient anti-foam control remedy necessitates a comprehensive evaluation of your special functional requirements.In the realm of anti-foam services, guaranteeing application compatibility is extremely important for achieving optimal performance.How does the ecological influence of an anti-foam control service influence your total choice procedure?In verdict, picking the appropriate anti-foam control solution necessitates a detailed assessment of particular application requirements, consisting of temperature, pH levels, and chemical compatibility (Anti-Foam Control Solutions). Adhering to these ideal practices will facilitate educated decision-making in anti-foam control solutions

Report this page